Examples

Utilization in concrete

Fly ash has a successful history of use in concrete around the world for over 50

years. In the United States of America more than six million tonnes and in

Europe more than nine million tonnes are used annually in cement and concrete.

So it is hard to think about concrete construction without considering the use

of fly ash. Some of the most prestigious projects of recent times have relied on

fly ash concrete, including dams, power stations, offshore platforms, the

Channel tunnel, highways, airports, commercial and residential buildings,

bridges, pipelines and silos. No wonder that fly ash is used in all sectors of

the concrete industry, covering ready-mixed, precast and on-site applications.

A number of prestigious constructions with fly ash concrete throughout Europe underline the importance of this valuable building material. The selection in this bulletin gives just one example per country. The level of experience and the variation of applications may be different from country to country. For more information contact ecoba or its member companies directly.

Benefits in concrete

Fly ash has some unique properties most useful to a wide range of industries,

such as civil engi-neering, construction and building. When fly ash is added to

concrete, it reacts with calcium hydroxide and forms stable hydrates of calcium

silicate and calcium aluminate. The resulting concrete is not only stronger and

more durable, but also less permeable. This makes concrete more resistant to

chemical attack. The reduction of the penetration of chlorides as well as the

sulphate resistance of concrete are improved by using fly ash. The addition of

fly ash to mass concrete is important to reduce crack formation due to the low

hydration heat.The particles of fly ash are spherical and act like ball bearings

in the mix, improving the work-ability and flow characteristics of concrete.

Additionally the fly ash improves the grading curve of the concrete mixture.

These features have a significant effect on water demand, and result in less

water being required.

Fine examples of application of minerals from coal can be seen throughout Europe:

|

building |

||

| Germany

The Castor and Pollux towers in Frankfurt are classical concrete buildings. The higher tower of this ensemble has a height of 130 metres. They are built on a single foundation mass concrete plate that contains 180kg cement and 120kg fly ash/m3 to obtain a low hydration heat. The upper layer of the foundation plate was designed for a high abrasion resistance containing 280kg portland cement and 70kg fly ash/m3. To increase the rentable floor space high strength concrete B65 was used for the towers containing 400kg cement and 100kg fly ash/m3 for the inner walls. The columns were produced from high strength concrete B115 with 470kg cement, 120kg fly ash and 35kg microsilica per m3. The strength of the columns reached up to 130N/mm2 at 90 days. |

Castor and Pollux towers, Frankfurt |

|

|

Picasso Tower, Madrid | Spain

For the construction of the Picasso Tower, 171metres high, in Madrid (the highest building in this city) concrete with fly ash addition has been used. 11000m3 of concrete were pumped and its admixture varied in function of the height. For the development and formulation of such a concrete, different recipes were tested, by using different types of lightweight aggregates, cements, fly ash and additives. The results of the tests carried out before construction showed that the most important parameters to be considered to ensure satisfactory pumping of the concrete and to obtain the required durability were the amount of fly ash, specific additives and the saturation rate of lightweight aggregates. The amount of cement had a minor influence. |

| The Netherlands

Self compacting concrete (SCC) is well known in Japan. Since 1995 SSC is under development for the precast and ready mix industry in the Netherlands. First technical experience with this new concrete were made with the ?Stadsschouwburg?, a new theater in Den Haag. For architectural reasons there are a lot of V-like horizontal profiles in the fassade, which could not be produced with conventional concrete. In SSC a new kind of plasticizers, the so-called ?hyperplaticizers? will adjust the workability of the concrete in terms of both flowing behaviour and plasticity, as well as cohesion and viscosity. Further the amount of aggregates is reduced in comparison to normal concrete, and the proportion of fine grains, that means the amount of cement and fly ash, is increased. The desired workability is obtained both by the action of the new plasticizer as well as by the complete encapsulation of the aggregate grains with a paste consisting of a mixture of fine grains and water. |

Theater in Den Haag. |

|

bridge |

||

|

Great Belt East Bridge | Denmark

To connect Copenhagen with the mainland of central Europe the East Bridge

project has to be completed to link the Danish islands of Funen and Zealand.

This bridge will be the world's longest suspension bridge, with a free main span

of 1624 metres. The pylons from which the main span is suspended will rise to a

height of 254 metres. They are constructed of in-situ reinforced concrete, but

are founded on prefabricated rein- forced concrete caissons. |

|

|

dam |

||

| France

The Puylaurent dam is one of the largest arch dams built in France in the past decade. It was completed at the end of 1995. Its maximum height is 73 metres over the foundation, with a crest length of 220 metres. The effect of adding fly ash into dam concrete is well known. It limits the exothermicity in the concrete during hardening, and decreases the risk of cracking due to thermal stress. A special binder was used composed of 60% blast furnace slag cement and 40% fly ash from a French thermal power station. The cement content was set at 250kg/m3. Using an innovative process for mixing fly ash into concrete wet fly ash from stockpiles was chosen to serve as an additive in the Puylaurent dam concrete. The quantity of ash used in all construction was 10000 metric tonnes. |

Puylaurent dam |

|

|

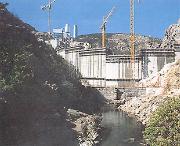

Planatovryssi dam | Greece

In 1992 Dimosia Epichirisi Ilektrismou (DEI) started with the construction of Planatovryssi dam, applying the roller compacted concrete (RCC) technique and utilizing fly ash as basic cementitious material. RCC is defined broadly as no-slump concrete compacted by roller, usually a vibratory roller. The design and construction of Planatovryssi dam is of great scientific and technical interest, since, for the first time in the whole world, such a big dam is constructed with roller compacted concrete (RCC), utilizing lignite fly ash. The dam, 95 m high, with a crest length of 270 m and a volume of 450000m³, is the highest RCC dam in Europe. The Planatovryssi dam is about 12 km downstream the 170 m high Thissavros rock fill dam and acts as the lower reservoir of Thissavros pumped storage plant of 300 MW. The RCC was made by 50 kg/m³ ordinary portland cement (PPC) with 225 kg/m³ milled and water-pretreated lignite fly ash, the mixture for facing consists in 140 kg OPC and 175 kg/m³ fly ash. |

|

silos |

||

| Belgium

The Genk-Langerlo power generating station has five concrete storage towers to store fly ash. Each storage tower is 43.60 metres high, with a diameter of 13 metres and a wall thickness of 0.45 metres. The so called ?gliding mold? method was used to cast the concrete, where 80kg of fly ash were added per m3. After 28 days the test samples reached a compression strength of 34.9 N/mm2. The total amount of fly ash concrete used to build the tower walls, top and bottom floors included, was approximately 1500 m3 per tower, which meant the addi-tion of 120 tonnes of fly ash. The use of fly ash did not give rise to any special precautions during construction. The fly ash concrete delivered a smooth and even surface. The technique has since been adopted at several other generating stations. |

Fly ash storage towers, Genk-Langerlo |

|

|

power stations |

||

|

Cooling tower Niederaußem, Germany | Germany

For the cooling tower of the new 950 MW power station at Niedraußem, Germany, a high performance concrete with high resitance against acid attack was produced. With a complete hight of 200 m, an upper diameter from 86 m and a lower diameter from 136 m this cooling tower is the biggest one worldwide at the moment. For the complete construction 32 000 m³ of concrete have been produced, for the scale 17 650 m³ high perfomance concrete were used. This special acid resistance concrete (SRB) is very dense and reaches a compressive strength of more than 85 MPa after 28 days. For static reasons 35 MPa would have been satisfactorily, therefore this concrete was named ?SRB85/35?. The dense matrix is resulting by an optimized grain size distribution, especially in the fine fraction consisting in cement, fly ash and silica fume. For the production of 1 m³ of this concrete nearly 230 kg ordinary portland cement, 65 kg fly ash and 33 kg silica fume as binder, 3200 kg of aggregates up to 16 mm grain size and 120 l of water beside a new generation of fluidizer on the basis of polycarboxylat was used. |

|

CCPs are utilised in a wide range of applications in the building and construction industry. The following pages contain examples showing the use of CCPs in a variety of applications, all of which serve to demonstrate the excellent performance of these materials.

Applications for CCPs include their use as an additive in concrete manufacture, as a cement replacement material, and as an aggregate or binder in road construction. They can also be utilised as mineral fillers and as fertilisers. Where necessary, CCPs meet any relevant national and European building materials standard and regulation.

|

windscreen |

||

| Netherlands

A fine example of the use of fly ash in large concrete structures can be seen near Rotterdam in the form of the windscreen situated along-side the Caland Canal. The purpose of the windscreen is to prevent large sea-going vessels from drifting in the canal as a result of strong winds. The structure is situated near the North Sea and is therefore exposed to severe conditions such as sand abrasion, saltwater and str The windscreen was slipformed in the early 1980s and has now become a famous landmark. |

Windscreen with hard coal fly ash, Rotterdamm |

|

|

offshore oil storage |

||

|

B.P. Harding Gravity Base Structure | England

The B.P. Harding Gravity Base Structure was built to store up to 570000 barrels of crude oil. The structure weighs 85000 tonnes and supports a 23000 tonnes heavy-duty jack-up drilling/production/accommodation facility. 36000m3 of concrete were placed before the structure was towed 540 nautical miles and then submerged in 100metres in the North Sea. The marine environment demanded an extremely durable concrete whilst the engineering demands of the structure itself required high strength yet lightweight concrete. The solution was concrete mix based on a sintered fly ash lightweight aggregate (Lytag) with a cementitious binder containing 30% fly ash (to B.S. 3892 pt1). The use of fly ash as binder helped control hydration heat and provide long term strength development. |

|

|

blasting grit |

||

| Germany

Boiler slag, a glassy material produced in slag tap furnace boilers, can be used as a blasting grit. Compared with silicious materials, boiler slag has the advantage of having no silicogene effect. It also has a higher abrasion effect than other commonly Due to its hardness and abrasive qualities, boiler slag can be used in either unprocessed or ground form. Typical grain sizes, ground and delivered, range from 0.09mm to 2.80mm. The particle density of boiler slag used as blasting grit is 2,500 to 2,600kg/m3 while the bulk density is typically 1,30 |

Boiler slag as, blasting grit |

|

|

road construction |

||

|

Fly ash in road base, Staffordshire | England

Hard coal fly ash has been used in Fly Ash bound Mixtures (FABM) for roadbase, sub-base and capping in road construction in the UK. FABM can be produced in three forms ? cement bound fly ash (CFA); granular material bound with fly ash and lime (GFA); and a 230 mm CFA roadbase consisting of 7% cement abd 93 % fly ash. In 1997, a 1km length of the A52 at Froghall in Staffordshire was reconstructed using a material known as GFA. The project consited of the removal of a 400 mm depth of existing pavement material, recycling off-site with addition of 12% fly, 3% lime, 27 % sand and 58 % recycled aggregate (5-20mm), and relaying as a 300 mm GFA layer under 100mm of new bitumous surfacing. GFA used in this project is a mixture of crushed graded coarse material, sand, fly ash, lime and water, where the fly ash and lime combination performs as a binder. |

|

| France

The use of fly ashes in road constructions is well practized in France for long time. In the north of France the enlargement of the RN 47 at Lens La-Basse in the department du Pas-de-Calais (north of France) was constructed on a length of 7,5 km with the use of nearly 50 000 tonnes of fly ash. The street profile is 40 to 50 cm natural aggregates as ground layer, 22 cm laser with 91 % of fly ash, 28 cm layer with 13 % fly ash, covered with two 7 and 5 cm high bitumous layers. |

Fly ash in road base, RN 47 at Lens La-Basse |

|

sand-lime bricks |

||

|

Production of sand-lime bricks with CCPs, Bochum | Germany

Bricks are commonly used in the walls of houses. Due to their special properties sand-lime bricks can play an important role in house construction. In Germany, sand-lime bricks are produced by using a calculated mixture of boiler slag, fly ash, lime and water to be pressed into a brick mould. Hardening of the bricks is carried out in autoclaves at a temperature of 190 degrees Celsius and approximately 14 bars pressure. A comprehensive selection of bricks of different shapes and sizes are produced for use in house construction. CCPs can comprize up to 95% of the mixture used in brick manufacturing. |

|